☆☆☆Instrument Computer Software Specification --- Ⅰ

<1> Chinese culture window software interface,

easy to learn and easy to operate,

fully functional.

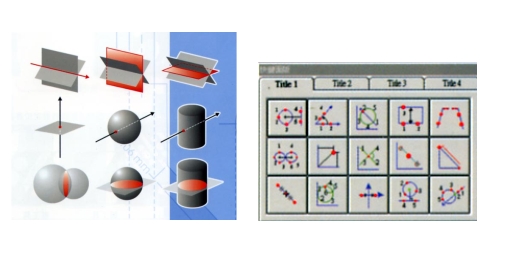

<2> Support Win 32 bit programming architecture,

the new design drawing processing functions,

3D stereo rotation is also the best tool for

CAD / CAM reverse engineering.

<3> Panel man-machine interface operation,

convenient, quick completion of measurement

and reporting.

<4> The new tree-like data shows the window,

easy to edit and call out in the calculus.

<5> Support electronic probe and optical image

probe common coordinate system function.

<6> Provide deviation curve analysis, for further

analysis of quality control units.

<7> Complete, accurate geometric measurement

function to meet the needs of all walks of life

measurement.

<8> Provide 60 sets of blank shortcuts for users to

establish their own ICON interface.

◇Complete geometric measurement function

△Basic geometric measurement function

◎Midpoint, line, circle, circle, face, ball, cylinder

(segment difference, cylinder, cone)and keyboard

input coordinate function Each measurement

function can be multi-point measurement size

can also be set to print or not.

△Geometric measurement function

◎True straightness, flatness, true roundness,

true sphere, cylinder degree, position degree,

parallelism, vertical degree.

△Workpiece coordinate system function

◎Face correction, bevel correction, origin setting

(arbitrary axis), axis correction, coordinate system

(rotation, memory, call out).

☆☆☆Instrument Computer Software Specification --- Ⅲ

(Three - dimensional graphic measurement system)

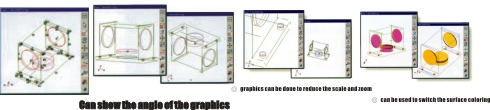

◇Support CAD / CAM reverse engineering

◎Workpiece measurement immediately graphical,

measured at the same time drawing window

synchronization drawing the measured workpiece

map.

◎The operator can clearly understand the current

measurement state, reduce the measurement error.

◎Graphics can be archived (DXF, IGES, BMP)

and transferred to CAD / CAM editing.

◎Graphics can be exhaled at any time and can

directly click on any element of the map for

geometric element operation or size of the

recalculation.

◎Graphics can be 3D stereo rotation, zoom in,

zoom out, local zoom, move, light, surface coloring.

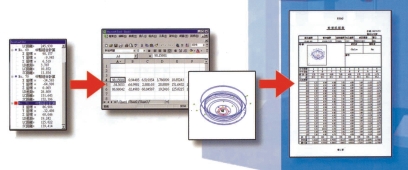

△Provide a variety of statistical analysis reports

◎ KCMM-PLUS Provide deviation curve analysis

and official report.

◎ KCMM-PLUS Provide a formal "test report"

to meet the general needs of the industry.

◎If the official "test report" can not be met,

you can set the form to paste the

workpiece map can also complete a

great "test results report."

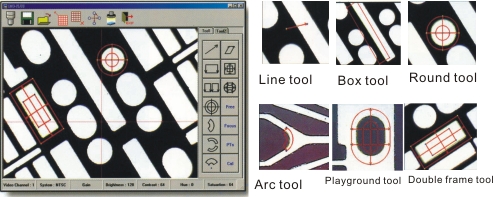

☆Provide three-dimensional optimal image measurement options

◇System characteristics

◎Provide automatic positioning of the image search tools,

measurement more quickly and accurately.

◎Add a video focus indicator for easy viewing.

◎Provide measurement direction indicator, easy to find the

next measurement point.

◎Use with KCMM-PLUS for best performance.

◎Support WINDOWS 98, WINDOWS ME, WINDOWS XP

operating platform.

◇Image automatically locates the edge finding tool

◎In addition to retaining the cross-line search function,

and provide users more convenient and quick "image

automatic edge search function", to avoid human

visual error, to provide measurement reliability,

measurement results will not vary, as long as the press

Mouse, quickly capture round, arc, line, box, a

substantial increase in measurement efficiency.

◇Measurement direction indicator

◎Provide the measurement direction indicator, in the

repeated measurement can follow the indicator to find

the next measurement point.