Unique innovative design

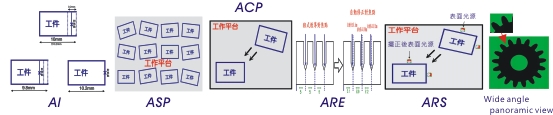

Vpro i = 4A + AI + ASP + ARE +ACP + ARS = Artificial intelligence

AI - Smart focus function / ASP- automatically for each workpiece

coordinates for batch detection

ARE- Automatically specify the reference feature / ACP-fast

image positioning automatic workpiece coordinate

alignment / ARS-automatic rotation light source.

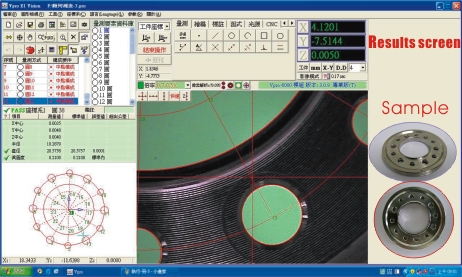

Unique new design : X / Y/ Z JOG image positioning

(mouse operation) & image panorama taking pictures.

※ AI Wisdom Focusing (Artificial Intelligence): for a single or

most of the focus to be done to do the focus offset

correction focus.

※ ASP For each workpiece automatically set ( AutoSynchronize

Position (Auto skew for every workpiece) Batchesting)

Batch detection:

If the majority of objects placed in the program and set the path

to teach a slight shift, you can use [ASP] automatically put the

system, the software will be a separate measurement of each

measurement [positioning]before the effective measurement

can continue to (to avoid Coordinate replication generated

when the progressive tolerance), the general measurement

software can not be carried out for batch inspection of eac

workpiece is straight and lead to measurement failure or error.

※ ACP Fast automatic alignment Auto Coordinates Position

=Fast auto coordinate position (Include skew)For a

single test material to quickly locate the measurement

1 to 5 seconds to complete the positioning does not

need to be placed on the fixed point.

※ ARE Automatically correct the measurement position Auto

Reference Element = Auto modify measured position

For the test object to allow tolerance procedures to

automatically modify, measurement.

※ ARS Automatic rotation of the light source (AutoLight Rotation

Skew) Auto modify light rotate When the measured parts

of the workpiece to measure the different angles of the

deflection into the light,the arbitrary change in the

workpiece position and angle, the program to teach the

implementation of ACP or synchronous workpiece

coordinates, the elements will be based on the original

light source angle automatically do light Rotation is

correct.

※General automatic light source refers to the program to teach

the light source will not automatically detect the workpiece

offset angle and do the light source to change the rotation.

※Full-view image scanning: the workpiece can be measured

beyond the lens part of the automatic image of the image

scanning, the formation of wide-angle panoramic view.

Software function design

<1> Windows operating system platform, graphics interface,

a substantial increase in efficiency,procurement costs

significantly reduced.

<2> Image image clarity and sub-pixel image technology to

improve the calculation of the calculation to make the

calculation more stable and accurate image and

then break.

<3> Geometric shape similarity setting and burr setting to

avoid misoperation and calculation after work forming

so that bad products will not be outflow.

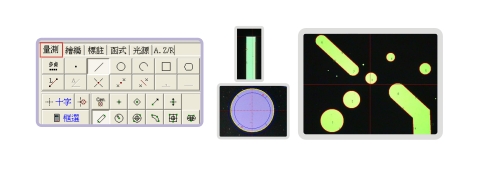

<4> Take the way to adopt: box selection edge, automatic

search edge, cross line point,mouse point to use each other.

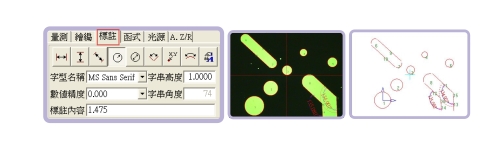

<5> Operation interface options: measurement, drawing,

labeling, function, light, auto focus parameters of the

graphical man-machine interface.

1> Measurement function: measuring point, line, circle, arc,

rectangle, groove, distance,intersection, angle ,,, and so on.

2> Drawing function: to provide auxiliary drawing points, lines,

circles, arc ,,, and other graphic elements of the revision,

so that the graphics easier to read.

3> Annotation function : To provide the measurement surface

and the measurement of direct labeling on the photoin

order to direct interpretation, at a glance.

4> Function function : Provide beginners, a single function of

operation, according to their own or habitual establishment

of graphical man-machine interface.

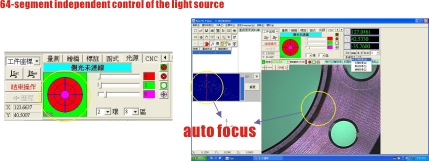

5> Light source function : Provide independent, multi-segment

(64) programmable rotary light source control and memory,

for 3D complex surface,due to light source and angle factors

can not be clearly pictured, resulting in can not be measured

or measured uncertainty.

6> Autofocus: Provides the correct, clear focus image, so that

each user will not cause errors due to human vision.

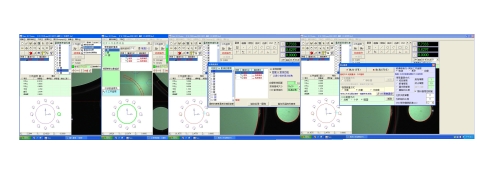

<6> Synchronize the workpiece coordinates: to provide the

operation of the sudden jump queue measurement;

if you continue to determine the coordinates can be

synchronized only.

<7> Auto CAD Import and export : Provide the measurement

data to compare the abnormal measurement and the

correct rapid test.

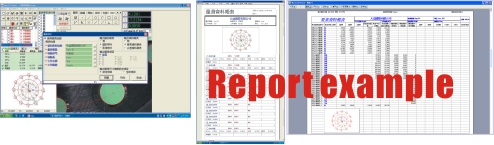

<8> Measure report export and specify excel fields : Provide

header, measurement picture,photo, tolerance,

measurement data synchronization output.

1> Measurement function : Measuring point, line, circle, arc,

rectangle, groove type, distance,intersection, angle ,,,

and so on.

2> Drawing function : Provide auxiliary drawing points, lines,

circles,arcs ,,, and other graphic elements of the revision,

so that the graphics easier to read.

3> Function function: Provide beginners, a single function of

operation,according to their ownor habitual establishment

of graphical man-machine interface.

4> Annotation function : To provide the measurement of

the surface and the measured photo directly marked

inch method to a clear, direct interpretation.

5> Light source function : Provide independent, multi-segment

(64) programmable surface light source control and

memory,for 3Dcomplex surface, due to light source factors

can not be clear imaging, which can not be measured or

measured uncertainty.

6> auto focus : Provide the correct, clear focus image, so that

each user will not cause errors due to human vision.

<7> Auto CAD Import and export : Provide the measurement

data to compare the abnormal l measurement and the

correct rapid test.

<8> Synchronize workpiece coordinates : To provide the

operation of the sudden jump queue determination;

if you continue to determine the coordinates can be

synchronized only.

<9> Array measurement function: to provide X / Y / XY /

rotary copy function; high efficiency to complete the

program production and accurate results.

<10> Tolerance setting function: Provide header,

measurement surface, photo, tolerance, measurement

data synchronization output and designated field.

<11> Measurement report export excel: provide the header,

measuring the surface, photos, tolerances, measurement

data synchronization output and designated fields.