【Hardware】

〒 Vpro All Series Unique innovative design『Cgk』core value:

3 A 、4 A、AI、ACP、ASP、ARE ARS Design and applicability

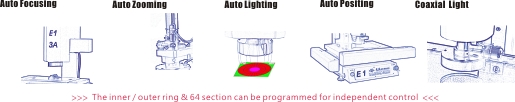

Auto Focusing : Its design to reduce the human visual focal length

error, resulting in the image is not clear,

measurement accuracy uncertainty

Auto Zooming : The design is to prevent the software and lens

correction after a number ofinconsistencies with

the measurement error.

Auto Lighting : It is designed to avoid the effects of measurement

accuracy and stability atdifferent times and under

light conditions.

Auto Positing : It is designed to quickly and accurately move to the

specified location todetermine the error in order to

avoid human errors.

〒 Vpro All Series ptical confocal, perfect center perfect performance --- 3um;

The systemthrough the actual test and repeat the automatic measurement

of theperfect precision.

〒 Vpro All Series Auto CAD *.dxf Format import, export measurement execution;

Graphical data is imported by performing measurements automatically by

performingactions and light sources as well as importing graphics and

measuringpatterns compared to presentation and tolerance fitting.

〒 Vpro All Series Blind hole (up / down view) concentricity measurement:

Only positive /reverse measurement can be done easily.

〒 Vpro All Series Side hole angle : Buy the fourth axis easy to complete.

【software】

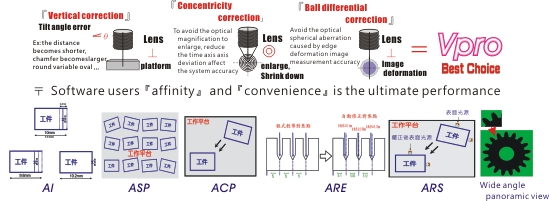

〒 『Optical lens』Extended design

『Standard optical lens』 R & D and equipped with their own R & D integrated systemprogrammable

control so that the measurement accuracy is no longer said that no.

『High power type optical lens』Integration of the United States Navitar Optical lens andequipped

with their own R & D integration can let the international come in.

『Light source system』Diversified design

Self-developed "64-zone" independent control of the light source system and equippedwith

the equipment to make three-dimensional workpiece edge comparison more clear measurement

more accurate.

Equipped with "coaxial light source system" to allow micropores, blind holes, low contrastedge

is more likely to produce significant contrast to increase the image clarity measurement easier.

〒 『Instrument life』Rigorous design

International brand linear slide carrying: X / Y / Z design for future precision and life perfect note,

so that domestic brands are no longer questioned.

Precision granite design equipped with: X / Y & base are designed to increase the center ofgravity

in addition to increase the temperature coefficient of expansion of the uncertainty considerations.

〒 Accuracy assurance and applicability

※ AI Wisdom Focusing (Artificial Intelligence): for a single or most of the focus to be doneto do the

focus offset correction focus.

※ ASP For each workpiece automatically set ( AutoSynchronize Position (Auto skew for everyworkpiece)

Batch testing) Batch inspection:

If the majority of objects placed in the program and set the path to teach a slight deviation,

the available [ASP] automatically set the system, such as the majority of objects placed in

the program and set the path slightly offset,you can use [ASP] automatically System,

progressive tolerance), thegeneral measurement software can not be targeted for batch

testing of each workpiece is caused by positive measurement failure or error.

※ ACP Fast Auto Pair Auto Coordinates Position = Fast auto coordinate position (Include skew)

For a single test material rapid positioning measurement 1 to 5 seconds to

completethepositioning does not need to be placed on the fixed point.

※ ARE Automatically corrects the measurement position = Auto modify measured position forthe test

object to allow tolerance to automatically modify the program, measurement.

※ ARS AutoPlace (AutoLight Rotation Skew) Auto Modify light rotate When the measured parts of the

workpiece to measure the different angles of the deflection into the light, the arbitrary change in

the workpiece position and angle, the program when the implementation of ACP or

synchronization Workpiece coordinates, the elements will be based on the origina l light source

angle automatically do light rotation is correct.

※General automatic light source refers to the program to teach the light source will not automatically

detect the workpiece offset angle and do the light source to change the rotation.

※Full-view image scanning: the workpiece can be measured beyond the lens part of the automatic

image of the image scanning, the formation of wide-angle panoramic view.